SPRING DESIGN SOFTWARE (SDS)

CUSTOMER SPRING DESIGN: CYBERDEBUG’s SDS offers a custom spring design service. Reasons for requiring custom spring design could include the customer working to tight space constraints or because specific performance requirements need to be met within the operation. Custom spring design from CyberDebug’s SDS means that the customer is going to be able to get exactly what they want out of a part CyberDebug’s SDS. Special forms and features can also be added during the design process, in order to enhance the spring’s properties or to aid compatibility with mating parts. Custom springs can be required within any industry sector, including automotive, aerospace, pharmaceutical and manufacturing. It really depends on the specific requirements of the spring itself. In particular when it comes to extreme working conditions, springs specified would normally be fabricated from the high end alloy wires, but it also comes down to practicality and meeting the performance requirements and the customer needs.

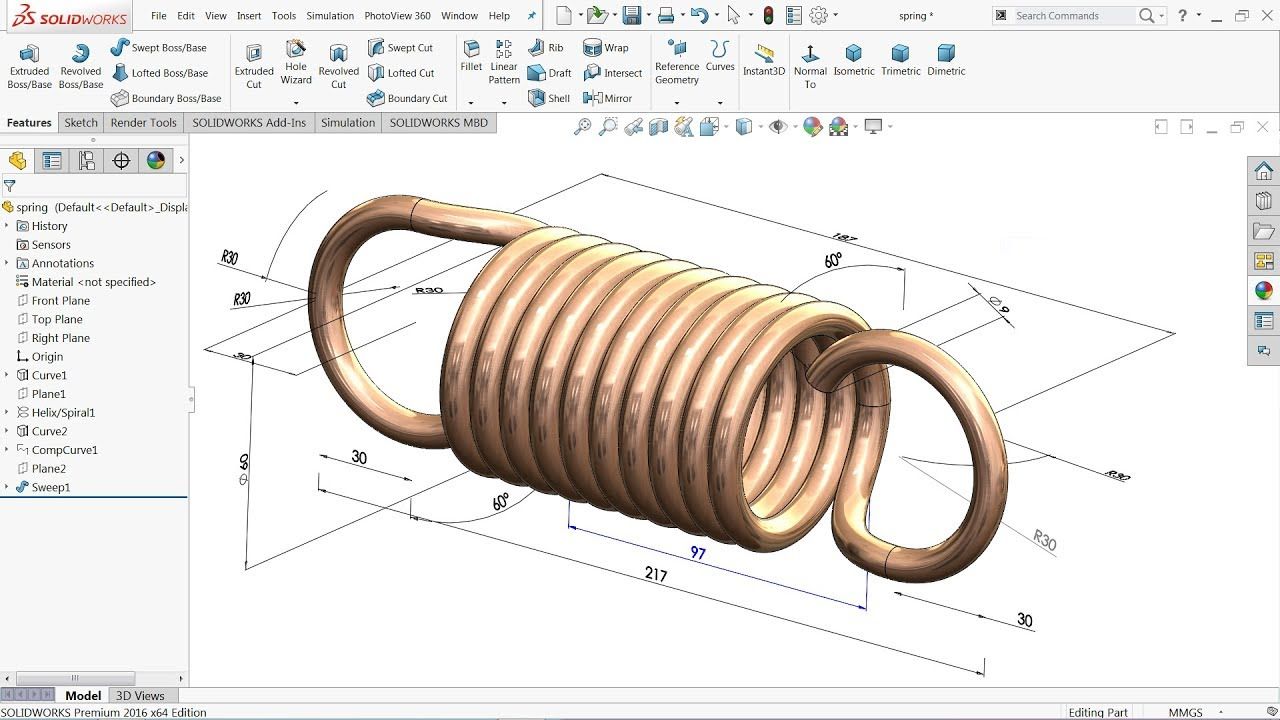

In order to specify a custom designed spring, the customer must first supply CyberDebug’s SDS with a specification form or assembly drawing. The key points that are taken into consideration for a new spring design are the size constraints of the spring, the required working load lengths, the environment the spring is required to work in and the functional longevity. The manufacturing process time often depends on the requirements of the customer. CyberDebug’s SDS works with the customer to their required timeline in order to deliver parts when required. To help with product development, CyberDebug’s SDS can also provide prototypes on a short delivery time if required. The size of a custom spring can vary depending on the requirements of the application. CyberDebug’s SDS can coil springs from a diameter of less than 1mm and at the opposite end of the spectrum, very large springs can also be manufactured. The materials used to manufacture custom springs, depend entirely in the application requirements for the spring. Some of the materials CyberDebug’s SDS uses include copper alloys, nickel alloys, standard carbon steels, all stainless steel grades and oil tempered wires. The company also uses higher end materials such as stainless steel, poly and 718. There is an almost limitless range of materials available to CyberDebug’s SDS, dependent purely on the application and the range available. CyberDebug’s SDS is making spring design easy with our amazing spring calculator. Our Spring Creator Calculator is composed of three individual spring calculators. The Spring Creator, spring calculation software, features a compression spring calculator, an extension spring calculator, and a torsion spring calculator all with amazing new features. The main features of the spring calculators are easy to measure inputs, spring load calculations, warnings and helpful tips, easy ways to determine if your design is "safe", custom blueprint generation, multiple spring design diagrams, stock spring suggestions, and our new Custom Spring Instant Quote. For spring design and measurement help please see the information below the calculator.